JMatPro calculates more nitrogen and chromium in solution than ThermoCalc does.

tions obtained by JMatPro and ThermoCalc, it is shown that Laves phase. Phase equilibria stable and metastable Freezing behavior and.

#Jmatpro 9 software#

Description: Using software JMatPro can do the following calculation to work.

#Jmatpro 9 cracked#

JMatPro 7.0 x86 full license Working with JMatPro 7.0 x86 full cracked 100 working.

#Jmatpro 9 trial#

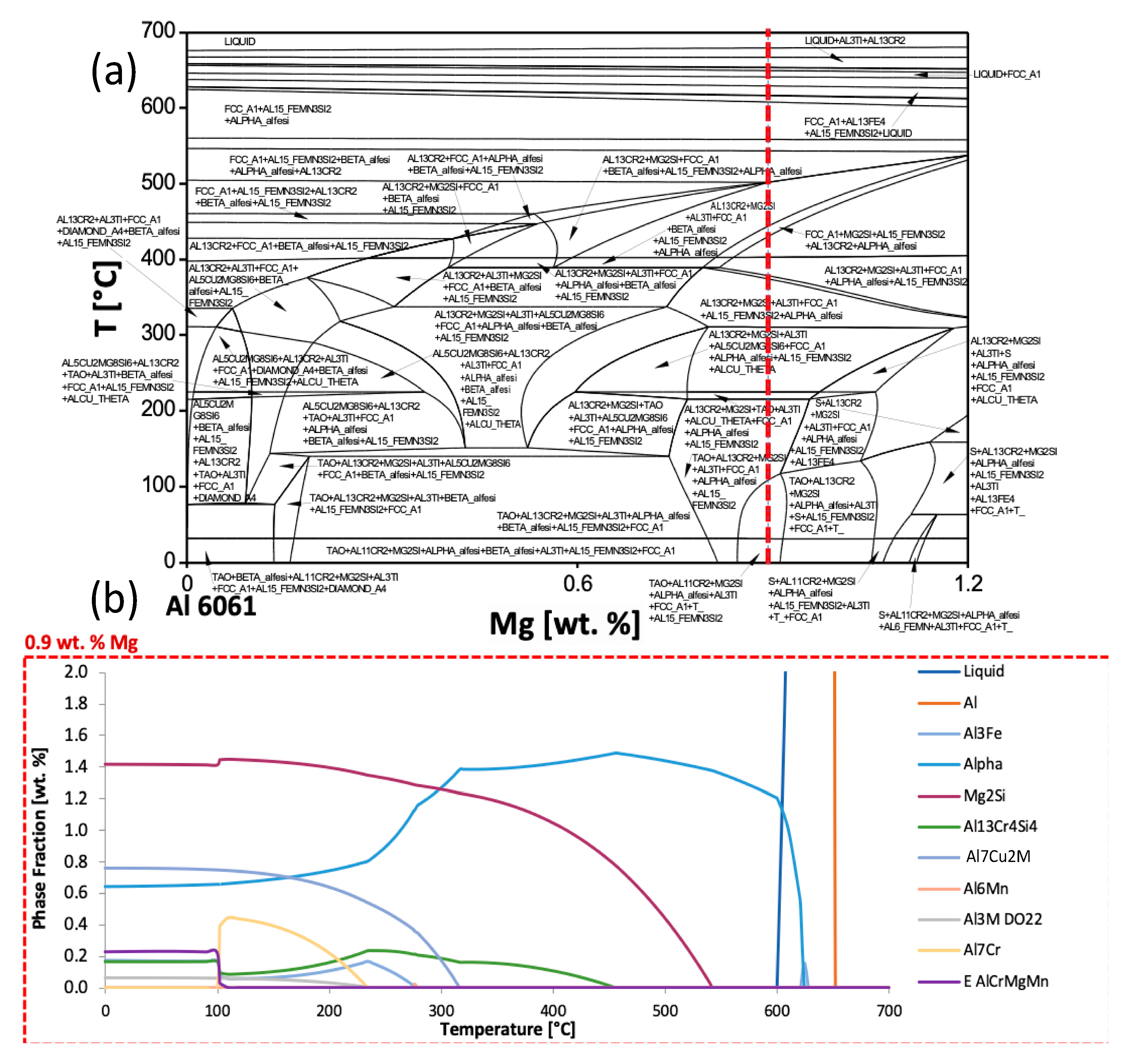

At different cooling rates, the continuous cooling transition diagram simulated by JMatPro is basically the same as the phase transition in the dynamic continuous cooling transition diagram of the test steel, which proves that the simulation prediction of the dynamic continuous cooling transition of the test steel by the JMatPro software has high accuracy and applicability. The Ms temperatures calculated using JMatPro alloy in solution are significantly lower than ThermoCalc. The microstructure of two Z-phase strengthened 9-12 Cr trial steels was studied. Download JMatPro 7.0 x86 full license 100 working forever Link download JMatPro 7.0 win32 full cracked working forever. With the increase of the cooling rate and the decrease of the transition temperature, from low-speed cooling→medium-speed cooling→high-speed cooling, respectively, the diffusion type phase transition→semi-diffusion type phase transition→the non-diffusion type phase transition. When the cooling rate is high (15☌/s), the martensitic transformation is a non-diffusion-type transformation carried out in the low temperature region, and the atoms are directly transferred from the austenite lattice to the martensite lattice. At a moderate cooling rate (1☌/s), the bainite phase transition is a semi-diffusion phase transition in which carbon atoms are displaced in a non-cooperative thermally activated transition mode. The results show that: at a lower cooling speed (0.1☌/s), austenite decomposition is a diffusion-type phase change that takes place in a high-temperature region, and carbon atoms can diffuse sufficiently. /rebates/2farticle2f10.10072fs40192-4&.com252farticle252f10. Obtain the dynamic continuous cooling transformation diagram and the scanning structure diagram of the test steel, and then analyze the phase composition under different cooling speeds through JMatPro material performance simulation. After the compression deformation, it was cooled to room temperature at different speeds. Through the Gleeble3500 thermal simulation test machine, the phase transformation law of Nb microalloyed steel was studied and tested. Software and databases such as Thermo-Calc 8, JMatPro 9, FactSage 10, or Pandat 11 have meanwhile become key tools for modern alloy development.

0 kommentar(er)

0 kommentar(er)